Polycarbin: Closing the Loop on Single-Use Scientific Plastics

A Call to Action

The scientific community is well aware of the devastating impact of fossil fuel consumption on our planet. However, awareness alone is not enough—what actions are we taking as an industry to address our contribution to the problem? Despite ongoing discussions about the environmental harm of single-use plastics, we have been slow to adopt innovative solutions that reduce our dependence on these unsustainable resources.

The Climate Cost of Lab Plastics

The biotech and pharmaceutical industries generate more than 200 million tonnes of CO₂ emissions annually, with 40% of those emissions stemming from the production and disposal of single-use items like gloves, PPE, and pipette tip boxes. These consumables are products of the take-make-waste economy, where finite raw materials are extracted, briefly utilized, and then discarded—contributing to the growing climate crisis.

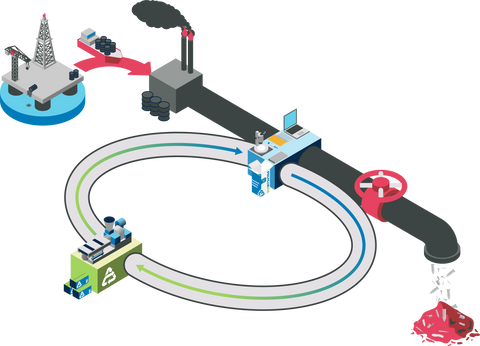

The Lifecycle of a Lab Plastic

Consider the lifecycle of a pipette tip box. It begins deep underground as crude oil or natural gas, oceans of fossil fuels that represent millions of years of sequestered atmospheric carbon. Extracting, refining, and converting these resources into plastic requires a tremendous amount of energy and produces shockingly low yields—five to seven times more carbon is consumed in the production process than is embodied in the final product. In essence, for every pipette tip box produced, 5-7 identical boxes are consumed as energy or lost along the way.

Once these plastics reach scientists, they are used for a few hours or even seconds before being disposed of into landfills or incinerators ultimately decaying into atmospheric CO2 over hundreds of years or immediately through combustion. This cycle is repeated millions of times every day, amplifying the environmental toll of single-use lab plastics.

The Problem with Downcycling

Historically, efforts to recycle single-use lab plastics have focused on downcycling—turning used plastics into products that cannot or will not be recycled again, such as park benches, paint buckets, and trash receptacles. While this adds an additional “use cycle” to the original material, downcycling fails to address the root issue for a couple reasons.

-

Disequilibrium: Labs generate 12 billion pounds of single-use plastic waste each year—far more than can be absorbed by reuse and low turnover industries like plastic lumber. This imbalance leads to oversupply, with excess plastic inevitably overflowing into landfills or incinerators.

-

Obfuscating Responsibility: When lab waste is diverted into unrelated industries, the scientific community loses control over the material. Scientists, who care deeply about sustainability and often recycle more than the average citizen, have no visibility into what happens to that plastic once it becomes a park bench or trash can.

- Opportunity Cost: Downcycling squanders the potential of high-quality lab plastics to displace even more virgin plastic. Scientific plastic is remarkably homogeneous, high quality, and uniquely suited for circularity. In short, pipette tip boxes, when recycled, make excellent PIPETTE TIP BOXES! Keeping these materials within their original ecosystem avoids supply-demand disequilibrium and maximizes recapture rates thereby compounding use cycles. A circular system for lab plastics can generate over 10 pounds of products for every pound of plastic produced, compared to just 2 pounds through downcycling. Each additional use cycle compounds the environmental benefits further minimizing the carbon impact of the original material.

Polycarbin’s Closed-Loop Solution

At Polycarbin, we’ve built a true circular economy for lab plastics using a data-driven, evidence-based approach. Every product we offer contains 20-100% circular economy resin, and we recycle every product we manufacture through our Closed-Loop platform. Unlike traditional recycling, our process ensures that lab plastics are remanufactured into the same products, preserving their value and reducing the need for virgin materials.

To ensure transparency and accountability, we conduct third-party audits of our supply chain using ISO 14040 and ISO 14044 certified Life Cycle Assessments (LCA). These supply chain audits are critical to powering our Carbin CounterTM Customer Dashboard and allow us to provide verifiable sustainability metrics, including:

- CO₂ emissions reduced

- Gallons of water conserved

- Kilograms of crude oil equivalents avoided

Nearly one-third of Polycarbin customers now use the Carbin CounterTM to power their annual Corporate Sustainability Reports, demonstrating how closed-loop practices translate directly into measurable impact.

Making Sustainability Attainable

Polycarbin offers an intuitive, practical path to starting your decarbonization journey. Most of our customers start with one of our various Mailback programs and ultimately graduate to large scale CORE ServicesTM whereby single-use consumables are recycled by the truckload.

Polycarbin offers out of the box solutions for labs of myriad types ranging from Food & Beverage QC Laboratories and Semiconductor Manufacturing to Research Institutions and Diagnostic Laboratories.

Join Us in Building the World’s First True Circular Economy

At Polycarbin, we believe that single-use waste does not have to be the cost of innovation. By reducing waste, cutting emissions, and empowering scientists to take action, we are building a new standard for sustainable innovation—empowering scientists to create true circularity.

Ready to see how much your lab can decarbonize?

Get in touch with us today for a consultation and learn how your lab can be part of the Polycarbin mission and help make science more sustainable!